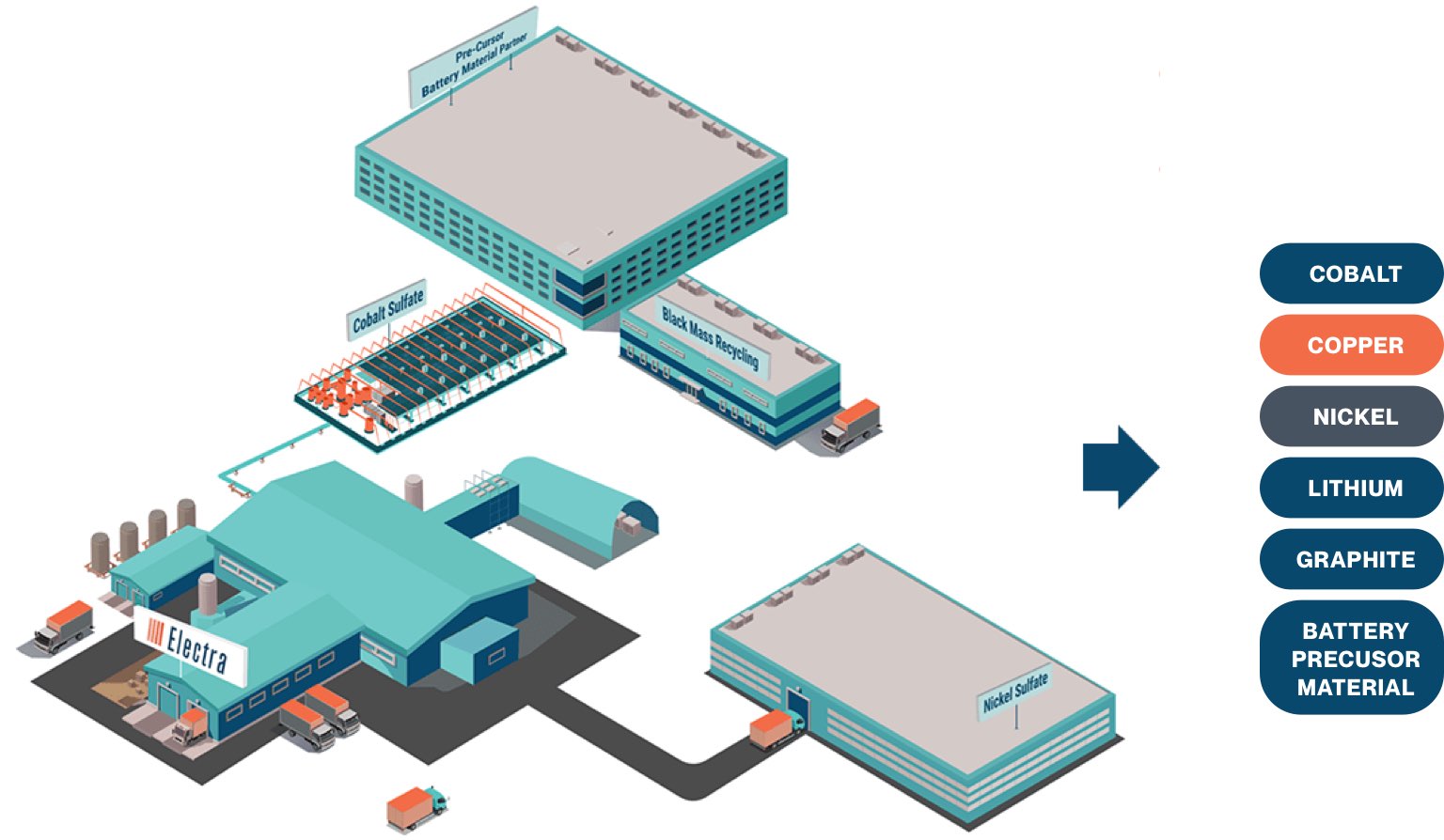

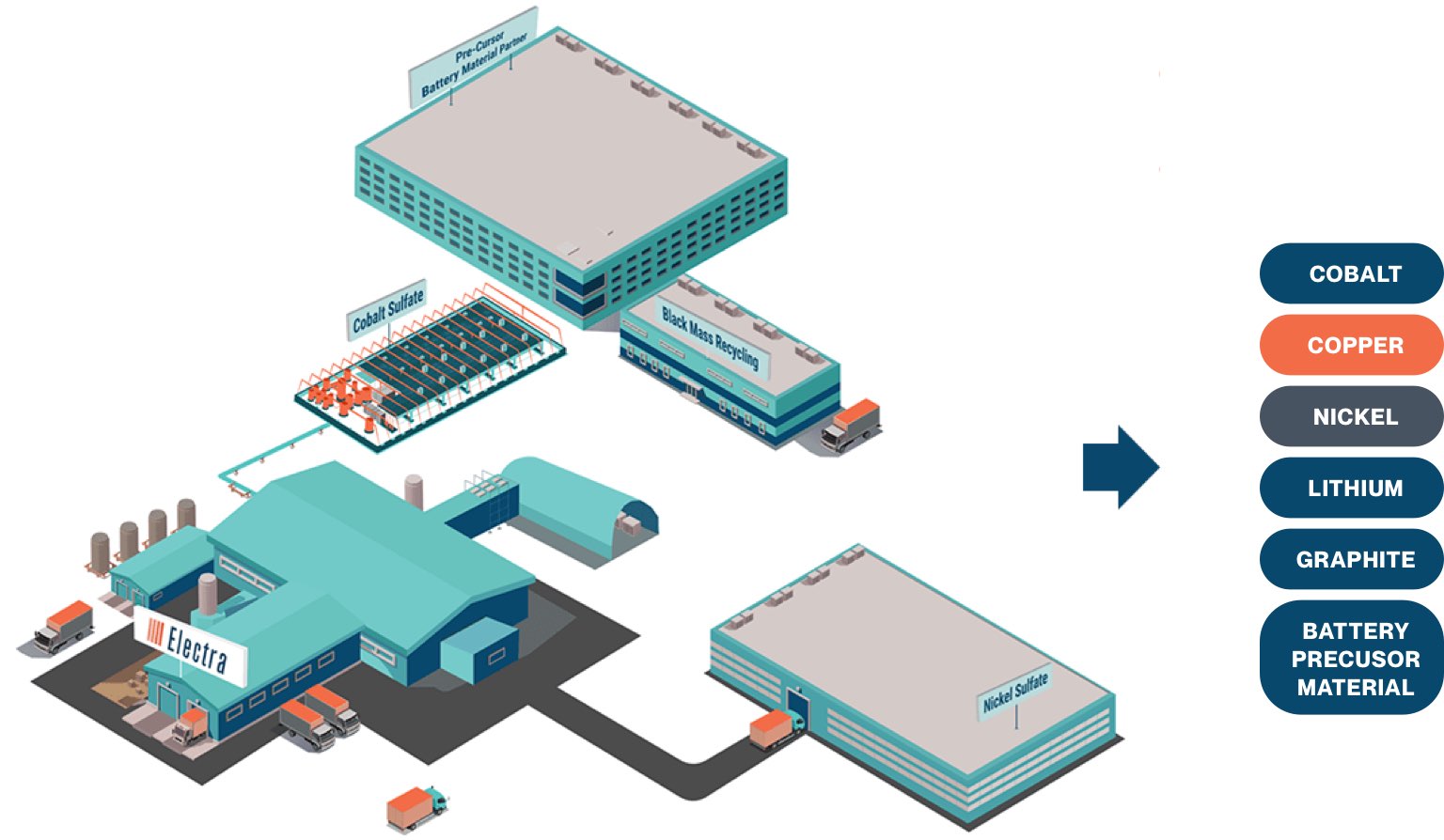

Phased Market Entry Strategy

Electra’s phased approach to market entry allows us to grow in line with demand from the evolving electric vehicle market, while minimizing risk and optimizing our capital deployment.

Electra’s hydrometallurgical facility is the only facility of its kind in North America. It will supply the electric vehicle market with cobalt sulfate, and has an operating history of previously producing cobalt carbonate and nickel carbonate.

Located in Ontario, Canada, near the largest auto manufacturing centres in North America, Electra’s products are produced locally. Our site is approximately 350 miles (600 kilometres) from the U.S. border and is accessible by road or rail. In addition to the renewable and affordable hydroelectricity that powers our site, Electra will produce the world’s lowest carbon solution for zero-emission vehicles.

At full capacity, Electra’s Ontario Refinery could produce enough cobalt sulfate to supply more than 1 million electric vehicles per year.

lower CO2 emissions

lower water consumption

lower eutrophication potential

lower global warming potential

Electra’s phased approach to market entry allows us to grow in line with demand from the evolving electric vehicle market, while minimizing risk and optimizing our capital deployment.