First Cobalt Announces Positive Feasibility Study Results for Canadian Cobalt Refinery Expansion

Strong project economics and growing EV market support development of

North America’s first battery-grade cobalt producer

TORONTO, ON — (May 4, 2020) – First Cobalt Corp. (TSX-V: FCC; OTCQX: FTSSF) today announced positive results from an independent feasibility study conducted on its permitted cobalt refinery in Ontario, Canada. The study contemplates expanding the existing facility and adapting it to be North America’s first producer of cobalt sulfate, an essential component in the manufacturing of batteries for electric vehicles.

The feasibility study demonstrates that the First Cobalt Refinery project can become a viable, globally competitive player in the North American and European electric vehicle (EV) supply chain. The study reinforces the strength of First Cobalt’s business strategy for a rapidly evolving EV market that is heavily dependent on supply from China.

FEASIBILITY STUDY HIGHLIGHTS

- Annual production of 25,000 tonnes of battery grade cobalt sulfate from third party feed, representing 5% of the total global refined cobalt market and 100% of North American cobalt sulfate supply

- Initial capital estimate of $56 million and an operating cost estimate of $2.72/lb of cobalt produced, which is competitive with global markets

- $37 million in undiscounted pre-tax free cashflow to the Project forecasted during the first full year of production

- $139 million after-tax net present value (NPV) using an 8% discount and 53% after-tax internal rate of return (IRR), representing a payback period of only 1.8 years

- Discussions underway with Glencore on commercial arrangements, financing and allocation of project economics; third party and government funding opportunities also under review

- Several EV manufacturers have expressed an interest in purchasing a North American cobalt sulfate

- Several opportunities will be evaluated over the coming months that could enhance project economics further, including alternative approaches to managing elevated sodium concentrations prior to returning process water to the environment

- Prefeasibility-level study also completed on an early ramp-up scenario using existing permits and equipment to conduct trial runs processing a different type of feedstock

All amounts in this news release are in US dollars unless otherwise indicated. Project economics are assessed over an initial 11-year period, however, the design capacity of a phase 1 dry-stack tailings area is 17 years. The feasibility study is not based on any existing mineral reserves or resources of the Company and does not contemplate that any of the Company’s current mineral projects will provide a source of feedstock for the refinery. A webcast and conference call will take place today, May 4 at 10:30 am EDT. Details are at the bottom of this news release.

| Table 1 – Feasibility Study Summary | |

| Key Assumptions | |

| Cobalt Price | $25/lb |

| Cobalt Hydroxide Payability | 70% |

| Cobalt Sulfate, Minimum Grade | 20.5% |

| Foreign Exchange (CAD:US) | 1.375 |

| Tailings Capacity, Phase 1 | 17 years1 |

| Capital Requirements | |

| Initial Capital Requirements | $56 million |

| Total Sustaining Capital | $0.6 million |

| Operating Costs | |

| Cobalt Production | $1.87/lb Co2 |

| Sodium Treatment | $0.85/lb Co |

| Total Unit Operating Costs | $2.72/lb Co |

| Annual Production Summary | |

| Cobalt Hydroxide Feed | 18,369 tonnes |

| Feed Grade | 30% Co |

| Annual Cobalt Production | 5,096 tonnes |

| Annual Cobalt Sulfate Production | 24,857 tonnes |

| Project Economics | |

| NPV – Pre-Tax (8% Discount Rate) | $192 million (C$263 million) |

| NPV – After-Tax (8% Discount Rate) | $139 million (C$191 million) |

| IRR – Pre-Tax | 64% |

| IRR – After-Tax | 53% |

| Cash Flow – Pre-Tax | $350 million (C$482 million) |

| Cash Flow – After-Tax | $259 million (C$356 million) |

| Post-Tax NPV (8%)/Initial Capital | 2.5 |

| Payback Period | 1.8 years |

1 Project economics calculated for the initial 11 years only. In aggregate, phases 1 and 2 of the dry stack tailings areas are expected to accommodate 34 years of production.

2 Does not include the purchase of cobalt hydroxide feed; however, project economics reflect a 70% long term payability assumption on feed and transportation costs

Trent Mell, First Cobalt President & CEO, commented: “This is an important milestone in our efforts to disrupt the existing cobalt supply chain. The study shows strong asset-level economics that position the refinery to be competitive globally and provide attractive investment returns. The outlook for electric vehicles and the push by automakers to develop shorter supply chains creates an excellent opportunity. With most of the world’s cobalt refining capacity located in China, there is strong demand for a North American alternative. Our focus will now turn to working with Glencore, our strategic partner, on implementing a new, ethical and transparent supply chain.”

Nico Paraskevas, Glencore’s head of copper and cobalt marketing added: “I would like to congratulate the First Cobalt team on a positive feasibility study. As the world transitions to a low-carbon economy, cobalt will play an essential role in the growth of mobility electrification. We look forward to working with First Cobalt to bring a sustainable source of cobalt to the North American market.”

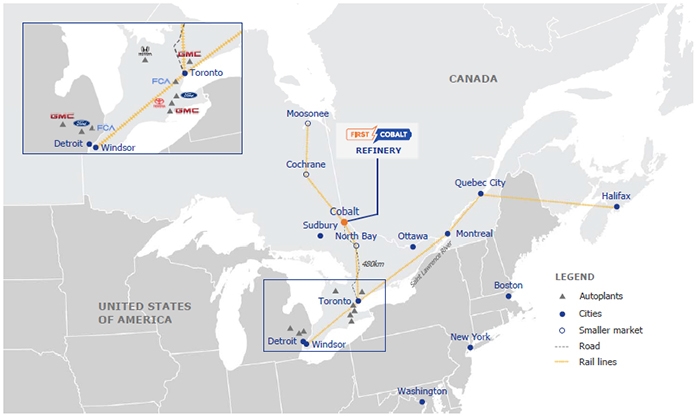

Project Overview

The First Cobalt Refinery is a hydrometallurgical cobalt refinery located north of Toronto, Canada (Appendix 1). The facility was permitted in 1996 with a nominal throughput of 12 tonnes per day (tpd) and operated intermittently until 2015, producing a cobalt carbonate product along with nickel carbonate and silver precipitate. The facility is located on 120 acres, with two settling ponds and an autoclave pond. The current footprint also includes a large warehouse building that once housed a conventional mill.

Testing of third-party cobalt hydroxide in 2019 using the Refinery flow sheet confirmed suitability of cobalt hydroxide as a source of feed to produce a high purity, battery grade cobalt sulfate.

In July 2019, First Cobalt and Glencore AG agreed to a partnership framework providing for a non-dilutive, fully funded, phased approach to recommission the Refinery. Subject to certain conditions, including the completion of a positive feasibility study and agreement upon commercial terms, the framework agreement contemplates that First Cobalt will treat cobalt feed material supplied from Glencore’s DRC operations for an initial term of up to 4½ years on a tolling basis, with Glencore providing up to 100% of the capital required to recommission and expand the facility. The objective is to produce approximately 25,000 tonnes of cobalt sulfate per annum for the electric vehicle market.

Ausenco Engineering Canada Inc. completed two studies in support of this strategic partnership: (1) a prefeasibility study on an interim recommissioning of the Refinery by late 2020 or early 2021 using exiting permits and equipment to qualify a cobalt sulfate product with end-users, and (2) a feasibility study on an expansion scenario to 55 tpd nameplate capacity, targeted for commissioning in Q4 2021. Details of the interim commissioning of a test plant are described further below under Demonstration Plant Scenario. The strategic objective of the partners is to achieve 5,000 tonnes per annum of cobalt production (55 tpd nameplate, 50 tpd average), which would account for approximately 5% of the current global refined cobalt market and an even larger share of the cobalt sulfate chemical market.

In conjunction with the feasibility study, discussions have been ongoing with potential automotive offtake partners as well as several lenders interested in providing a portion of the capital cost along with Glencore.

The feasibility study assessed the project economics of the Refinery on a stand-alone basis, assuming a 70% payability factor on the cobalt content of a cobalt hydroxide feed source based on expert forecasts for future payability levels (today’s spot payability is 62-65%). In order to secure the capital required and a reliable feed source, First Cobalt and Glencore will use the results of this study to negotiate terms of a two- to five-year tolling agreement and financing arrangement. As such, the cash flow generated from the Refinery will be shared between the parties and remains subject to ongoing discussions.

Cobalt Market

According to a report commissioned from Benchmark Mineral Intelligence, there are currently no plans to commission new cobalt refineries outside of China other than First Cobalt. They also note that most automotive companies outside of China are interested in sourcing cobalt sulfate closer to their manufacturing facilities or from suppliers located outside of China.

Other key findings in the Benchmark Mineral Intelligence report are as follows:

- China now accounts for approximately 79% of the world’s refined cobalt sulfate production and this is projected to increase further

- Cobalt demand from nickel-cobalt-manganese (NCM) batteries used in EVs will increase from approximately 20,000 tonnes in 2019 to over 730,000 tonnes in 2040

- Average payability over the last two years for cobalt hydroxide feed material has been at 68% of the average of the low of the monthly Metal Bulletin Low Grade Cobalt price

- Long term cobalt price forecast is approximately $59,100 per tonne or $26.81 per pound

Benchmark notes that demand for cobalt in lithium ion batteries will dominate all other demand categories and forecasts a structural deficit within the next five years.

Refinery Design Details

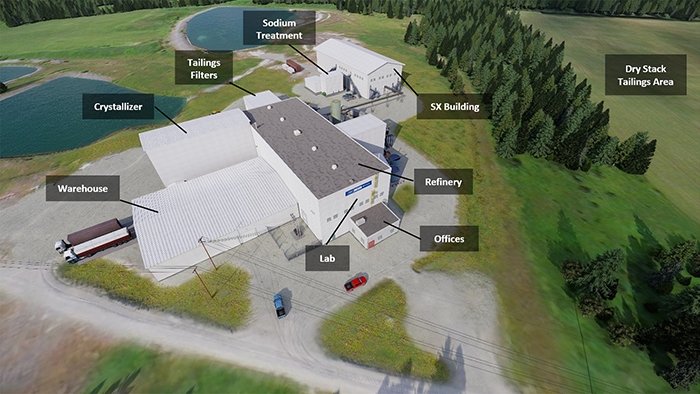

The First Cobalt Refinery sits on a 40-acre land package and includes the refinery building complex, one tailings pond (the Autoclave Pond) and two water treatment ponds (the “Upper” and “Lower” ponds). The main refinery gallery in the building complex houses the pressure oxidation circuit, solvent extraction circuit (SX), product filtration and a control room. The main building also includes a laboratory, administrative offices and changerooms. Other structures attached to the main gallery include a warehouse which previously housed a conventional milling circuit, a Merrill-Crowe building, a mechanical shop and a High-Density Sludge (HDS) building. There is also an external tank farm located along the north side of the complex. The feasibility study criteria were to make the best use of existing infrastructure while keeping as much as possible within the current footprint.

The proposed new layout adds two new simple engineered structures to the main complex; one for tailings belt filters and the other for crystallization and product bagging. A new external building is also contemplated to house an expanded SX circuit and sodium management infrastructure. Other changes to the site layout include additional tankage for reagent storage in the tank farm area and improvements to the ring-road around the refinery to accommodate transport trucks (Appendix 2).

An 80-acre property located to the north is owned by First Cobalt and it will be the location of a new dry stacked tailings management facility. Tailings from the process are a gypsum that can be readily dewatered and stacked for permanent dry storage. First Cobalt has the advantage that the field to the north is underlain by more than 6 metres of clay, some of which will be excavated to increase storage capacity, with the excavated clay being reused to construct the new tailings storage facility and permanently rehabilitate the Autoclave pond and the new tailings facility at end of Project. Only half of the field to the north is planned for the new tailings management facility, which will have approximately 17 years of storage capacity. The other half of the field remains available to be developed as additional storage for an additional 17 years of operation. The existing Upper Pond will be expanded to collect surface water from freshet and summer storm events for safe return to the environment.

Retrofitting of the existing buildings and equipment, new construction and installation of new equipment is expected to take approximately 12 months.

Cobalt hydroxide feed is expected to arrive at the Port of Montreal via ocean freight where it will be transferred onto rail cars to be delivered to a siding on the Ontario Northland railway in Cobalt, Ontario. The Ontario Northland rail line passes 2 km west of the Refinery Road. Hydroxide feed will be trucked from the rail siding to the Refinery and refined cobalt sulfate product will be backhauled to the siding for reloading onto rail cars for shipment to end markets.

Process and Metallurgy

Cobalt hydroxide feed material will arrive in bulk bags and be unloaded into the Refinery warehouse. The bulk bags will be lifted with the Refinery’s overhead crane, where the bags will be emptied into a re-pulping system. The slurry is then pumped to a leach circuit where it is leached with sulphuric acid under atmospheric conditions.

Slurry exiting the leach tanks is pumped to the neutralization circuit where limestone is added in order to raise the pH and precipitate impurities such as iron. To minimize downstream scaling, the slurry is cooled to 30-35°C in a cooling tower which reduces soluble gypsum content. The precipitated solids are removed through thickening and filtration.

Prior to solvent extraction (SX), the solution is re-heated to raise gypsum solubility and prevent subsequent precipitation in the mixer settlers. The first SX circuit is Impurity SX (ISX), targeting the removal of impurities such as manganese, copper, zinc, calcium, and iron. The extraction raffinate after this step primarily contains cobalt, with nickel and magnesium present as impurities. The strip liquor reports to effluent treatment, where the impurities are precipitated and removed from solution prior to discharge.

The second SX circuit is Cobalt SX (CoSX) which loads cobalt onto the organic solvent while any residual impurities remain in the aqueous phase. The cobalt-loaded organic then proceeds to the scrubbing mixer-settlers where the pH is adjusted to remove impurities such as magnesium and nickel that were loaded in the extraction stage. The scrubbed organic goes to a final stripping stage where the pH is lowered to bring the cobalt out of the organic phase and into the aqueous strip liquor stream. Once filtered to remove entrained organic, the strip liquor enters the crystallization step.

The filtered strip liquor is pumped to a mechanical vapor re-compression forced circulation crystallizer. The crystallizer functions by evaporating water using steam in a heat exchanger, supersaturating the cobalt-rich strip liquor and causing crystallization to occur. The bleed stream of cobalt sulphate crystals reports to a thickener and centrifuge for dewatering. Together they separate the solid and liquid components of the slurry, producing a dewatered product at <3% free moisture. The centrifuged crystals then report to a fluid bed dryer to reduce the moisture content of the crystals to below 0.2% w/w. Once dried, the final product is bagged and is ready for onward shipment to the end customer.

Tailings Storage Facility

Knight Piésold Ltd. completed geotechnical drilling on the potential dry stack tailings area in First Cobalt’s 80-acre clay field to the north of the Refinery complex to support feasibility-level design work. Dry stack or filtered tailings have several benefits, including a smaller environmental footprint and lower water treatment requirements.

The current design contemplated using approximately half of the field, providing capacity for 17 years of production at 50 tpd (55 tpd nameplate). Thereafter, it is envisioned that the other half of the field could be used for an additional 17 years of dry tailings storage. It is believed that additional land would be readily available for future expansions. For the purpose of assessing project economics, Ausenco has assumed an 11-year project life.

Water Management

Process water from the Refinery will be treated to a level that meets or exceeds regulatory requirements before being returned to the environment. Environmental testing and design by First Cobalt’s consultants have devised a treatment process to ensure that the return of process water to the environment is done in a compliant and environmentally friendly manner. Broadly speaking, there are two main criteria that must be met before water can be discharged. First, metals and other elements as prescribed cannot exceed predetermined thresholds. Second, the water being discharged should not be acutely toxic to aquatic life.

Owing to the use of sodium hydroxide in the process flowsheet that has been designed, effluent from the refining process would have an elevated concentration of sodium. There are no federal or provincial discharge limits nor surface water quality objectives or guidelines for sodium. However, it was determined that the amount of sodium in the effluent could be toxic to aquatic life. In order to satisfy the requirements of a feasibility level study, the study contemplates installing an established technological solution of evaporation and crystallization to remove sodium content.

The evaporation and crystallization technology is proven to be effective for removing sodium from the effluent but it is more expensive than other alternatives. In this process, the effluent stream is first concentrated by evaporation to reduce the volume reporting to the crystallizer. The resulting brine is then fed to a sodium crystallizer in which a crystalline sodium sulfate product is formed. This crystalline product is sent for offsite disposal.

First Cobalt identified a number of other solutions for managing the sodium that could significantly reduce capital and operating costs, including substituting sodium-based reagents for alternatives not containing sodium, making process changes or implementing other management solutions to reduce the sodium concentration in the effluent. Due to time constraints, Ausenco recommended that the study incorporate a well-established treatment process and that alternatives be more fully assessed over the next few months.

The capital cost for the selected method is $9.4 million representing almost 17% of the total capital cost. The operating cost associated with the selected method is $0.85/lb Co produced representing 31% of the total operating cost. First Cobalt and its consultants believe that there is significant opportunity in other sodium management methods that were reviewed but not in sufficient detail to be incorporated into this feasibility study.

Operating Costs

Operating costs are expected to average $30.7 million per annum or $2.72 per pound of cobalt produced over the project life. Total operating costs are expected to average $1,673 per tonne of hydroxide processed.

The breakdown of unit costs is summarized as follows:

| Table 2 – Annual Operating Cost | ||

| $/lb | $million/yr | |

| Labour | 0.23 | 2.6 |

| General Maintenance | 0.07 | 0.8 |

| Site G&A | 0.13 | 1.4 |

| Subtotal Fixed Costs | 0.43 | 4.8 |

| Reagents & Operating Consumables | 1.31 | 14.8 |

| Power | 0.12 | 1.4 |

| Sodium Management | 0.85 | 9.61 |

| Lab and Assay | 0.01 | 0.1 |

| Subtotal Variable Costs | 2.29 | 25.9 |

| Total | 2.72/lb Co | 30.7 |

1 See Next Steps and Project Opportunities

Fixed costs represent just 16% of the operating costs. The largest variable costs are Reagents & Operating Consumables, followed by sodium management costs (including offsite disposal). Ausenco has recommended that the Company assess alternative solutions to manage sodium in the effluent that, if successful, could result in a significant drop to operating costs and the initial capital costs (see Water Management above).

Capital Costs

The initial capital cost for the Project is $56 million and has been developed assuming an EPCM execution strategy. The onsite pre-production period spans 12 months.

A breakdown of the capital requirements is detailed below.

| Table 3 – Capital Cost ($ millions) | |

| Mechanical Equipment | 13.5 |

| Electrical Equipment | 2.2 |

| Piping | 3.2 |

| Architectural | 1.3 |

| Platework & Tanks | 5.8 |

| Structural Steelwork | 1.6 |

| Instrumentation Equipment & Bulks | 1.6 |

| Dry-stack Tailing Facility | 1.2 |

| Concrete | 0.8 |

| Sodium Removal | 9.41 |

| Other Directs | 0.8 |

| Subtotal Direct Capital | 41.4 |

| Engineering Procurement Construction and Management (EPCM) | 3.9 |

| Spares & First Fills | 2.5 |

| Field Indirects | 1.5 |

| Other Indirects | 1.5 |

| Subtotal Indirect Costs | 9.4 |

| Owner’s Costs | 1.0 |

| Contingency | 4.2 |

| Total Capital Cost | 56.0 |

1 See Next Steps and Project Opportunities

The feasibility study capital estimates are accurate to +/- 15% and includes a $4.2 million contingency.

Sunk costs related to previous owners’ investments of approximately $75 million are not reflected in the total capital estimate of $56 million. Previous investments include access roads, power lines, tailings management facility, the refinery building, adjacent warehouse and existing equipment.

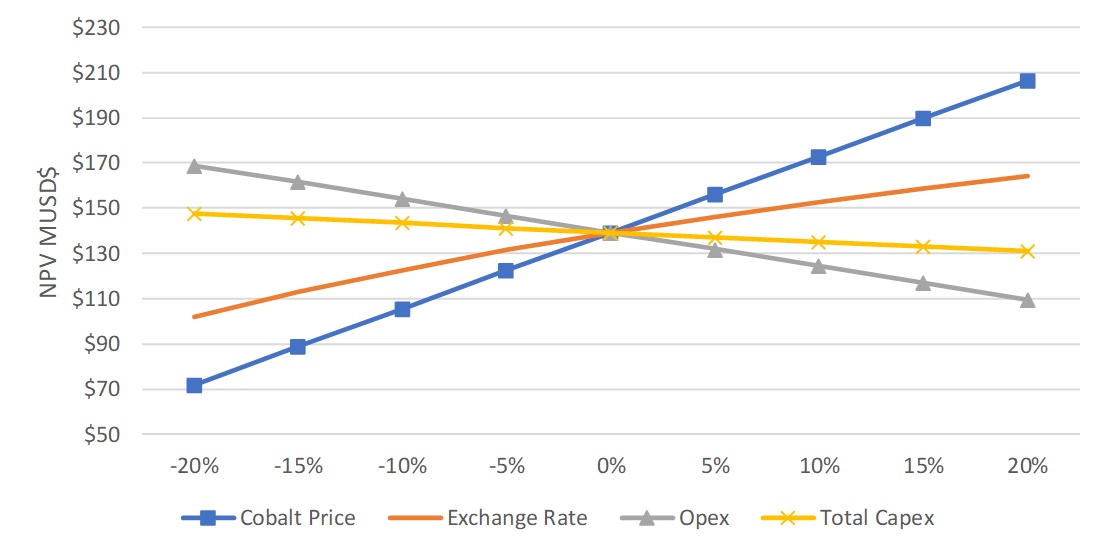

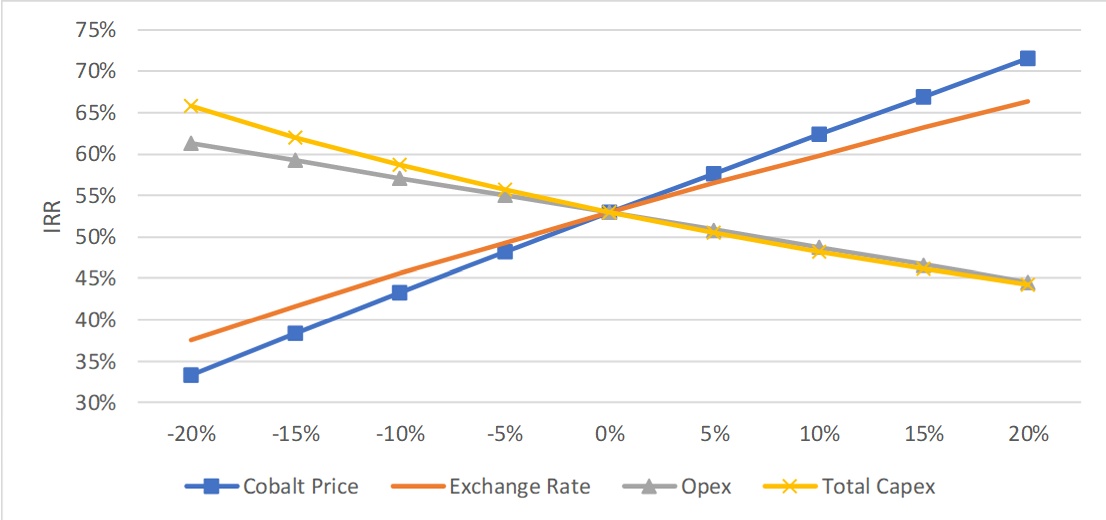

Sensitivity Analysis

The Refinery Project sensitivity analysis was performed on cobalt price and foreign exchange, as well as changes to Capex and Opex, as presented in the graphs below:

Figure 1 – Post-Tax NPV Sensitivity

Figure 2 – Post-Tax IRR Sensitivity

Permitting

Regarding the ability of First Cobalt to legally operate the Refinery under the current regulatory regime in Ontario, three environmental approvals and a closure plan amendment are required. The Air Environmental Compliance Approval (Air ECA) and Industrial Sewage Works ECA have been submitted, approved and amended from time-to-time by previous owners of the Refinery and remain in good standing. The Permit to Take Water (PTTW) is the third environmental approval and requires renewal from time-to-time. As the Refinery has not operated since mid-2015, the current PTTW has expired. First Cobalt and Story Environmental prepared a new PTTW application, consulted with local Indigenous Communities and subsequently submitted the PTTW application in March 2020. Under normal circumstances, First Cobalt’s consultants have advised that the new PTTW might be expected within 6 months of submission.

The Refinery has a Closure Plan on file with the Ontario Ministry of Energy, Northern Development and Mines (ENDM). In October 2019, the Company was granted a transfer of the Closure Plan from the previous owner to Cobalt Camp Refinery Ltd., a wholly owned subsidiary of First Cobalt. In conjunction with the transfer, First Cobalt also increased the amount of Financial Assurance held as cash by ENDM.

With the exception of the PTTW which the Company expects to receive in due course, the Refinery has all the necessary approvals in place to restart production at its permitted feed rate of up to 12 tpd.

For the expansion scenario envisioned by this feasibility study, the Air ECA, Industrial Sewage Works ECA and the Closure Plan will all require amendment to reflect the new operating and environmental regimes. Work has already begun collecting baseline and other data in support of these ECA amendments. First Cobalt currently expects to be able to make the application for these ECA amendments before the end of 2020. Based on the feasibility work conducted to date, no hurdles have been identified which would compromise the approval of these applications. Indigenous Community and public consultation will be continuing throughout the ongoing scoping studies and the approval process.

Demonstration Plant Scenario (12 tpd Restart)

In tandem with the feasibility study, the Company completed a prefeasibility level assessment of an early restart of the Refinery using existing permits and equipment to operate at 12 tpd. The resulting prefeasibility report was intended as a benchmark from which various restart scenarios could be assessed.

Key differences in the 12 tpd demonstration plant scenario compared to the 55 tpd feasibility study include: (1) treatment of a different cobalt alloy feedstock with higher reagent requirements that significantly increases operating costs, and (2) continuing to use the current tailings management facility rather than the dry-stack tailings design included in the 55 tpd feasibility study.

A site field inspection program was completed in Q4 2019 to assess the condition of existing equipment and identify the equipment that can be refurbished, reused or repurposed. The field inspection program concluded that the Refinery remains in good condition for a quick restart and quantified the scope of work for the capital cost estimate.

The scope of the study included all areas within the existing refinery building, from feed preparation to final product bagging, reagents, utilities, water circuits, existing laboratory and offices, incoming power and the existing tailings management facility. The existing processing configuration would be modified based on receipt of a cobalt feed containing alloy and production of cobalt sulfate through leaching, neutralization, SX, ion exchange (IX), and crystallization unit operations. The development of the process design criteria and flowsheet modifications were based on recently completed metallurgical test work results and METSIM™ modelling.

Metallurgical test work program included leach testing, partial neutralization of pregnant leach solution, impurity SX and scrubbing, cobalt SX and scrubbing, cobalt precipitation, impurities precipitation and solids-liquids separation testing. Cobalt extractions exceeded the design value of 93% and the resulting cobalt sulfate product graded 21.4% cobalt.

The refinery would operate under the existing Air and Noise ECA, Industrial Sewage Works ECA and Closure Plan. An application for a new a Permit to Take Water has been submitted, as mentioned above.

The operating and capital cost estimates were prepared in accordance with a Class 4 (PFS) estimate with an accuracy of ±25%. Operating cost for the cobalt alloy product was estimated at $6.88 per pound of cobalt produced and the capital cost was $12.1 million plus $1.3 million contingency. The Company is now assessing how much of the capital cost would be credited against the 55 tpd capital cost estimate.

The prefeasibility study concludes that an early recommissioning scenario using existing permits, facilities and equipment is feasible, subject to a few changes to the current flow sheet and other plant modifications. First Cobalt and Glencore are reviewing the report to determine the optimal path for a demonstration plant that could produce cobalt sulfate for EV battery product qualification as early as Q4 2020.

Using the prefeasibility study as a benchmark, three scoping studies are underway to assess alternate early commissioning scenarios. In the first scenario, the Refinery throughput would be reduced below 12 tpd in order to reduce the capital costs of a restart while allowing the Refinery to operate as a demonstration plant to qualify cobalt sulfate product according to EV manufacturer specifications. Under a second and third scenario, the Refinery would be initially restarted at 12-tpd as a demonstration plant and over time would be retrofitted with a nominal 43-tpd hydroxide circuit and then either combined into a single circuit or left as two circuits capable of receiving different feedstocks. Results from the prefeasibility study and the three scoping studies will guide the Company’s restart strategy.

Project Opportunities

The feasibility study outlines a path to commissioning a globally competitive cobalt refinery to service North America and Europe. Potential remains for further improvements in Project economics which will form the basis of ongoing evaluation work. Some of the other opportunities that First Cobalt will pursue include the following:

- Utilizing a different technology or approach to managing sodium could have significant positive impacts on both capital and operating costs. The Company plans to assess alternative options with the goal of enhancing overall project economics.

- The crystallizer selected for the feasibility study (capex of $4.3 million) is intended to achieve the highest quality of cobalt sulfate ‘heptahydrate’. However, various potential offtake partners have indicated a higher tolerance for other hydrates of cobalt sulfate, such as monohydrate or pentahydrate, provided that cobalt content is known and moisture is controlled. As a result, the Project might realize a significant savings by using a different crystallizer.

- The financial model in the feasibility study assumed a cobalt recovery of 93%, based on a batch metallurgical testing and METSIM™ modelling that yielded a 93.3% recovery. However, the Company and its advisors believe that recoveries in excess of 95% can be achieved through additional pilot plant testing of the SX circuit under conditions of continuous operation where “lost” cobalt is recycled back through the circuit and subsequently recovered. Batch testing conducted to date does not adequately reflect this operating scenario.

- The phase 1 dry stack tailings design has 17 years of storage capacity whereas the financial model assumes an 11-year project life. The Refinery can continue operating indefinitely provided sustaining capital expenditures are made to maintain and replace parts and equipment over time. By extending the financial model for the entire 17 years of the phase 1 tailing design or the 34 years for phases 1 and 2, the NPV is expected to have a material increase.

Next Steps

The Company expects to continue to advance and de-risk the Project in 2020 by pursuing the following activities:

- Completing the three scoping studies to help identify the best path forward to recommission the Refinery using existing permits

- Assess other sodium management technologies and options that could significantly reduce capital and operating costs

- Advance discussion with Glencore discussions on commercial terms for a toll-treatment arrangement and financing alternatives

- Advance funding discussions with third parties and government agencies

- Continue to work with Glencore to advance long term offtake discussions

- Advance environmental approval activities to shorten timeline for regulatory approvals

- Target completion of a development plan within the next 90 days

Technical Reports

Further information about the 55 tpd feasibility study, including data verification, key assumptions, parameters, risks and other factors referenced in this news release, will be provided in technical reports that the Company will file on its website and on SEDAR at www.sedar.com in the next few weeks. The 12 tpd prefeasibility study will also be made available on SEDAR for reference.

The feasibility study technical report will be prepared in accordance with NI 43-101 form guidelines however the report does not constitute a “feasibility study” within the definition employed by the Canadian Institute of Mining, Metallurgy and Petroleum (CIM), as they relate to the Refinery and do not concern a “mineral project” of the Company. As a result, National Instrument 43-101 – Standards of Disclosure for Mineral Projects is not applicable to the scientific and technical disclosure in this press release.

The following independent authors have reviewed and verified that the technical information in respect to the feasibility and prefeasibility studies in this press release is accurate and approve the written disclosure of such information.

| Ausenco Engineering Canada Inc. | Tommaso Roberto Raponi, P. Eng. |

| Knight Piésold Ltd. | Andy Phillips, P.Eng |

| Story Environmental Inc. | Maria Story, P.Eng. |

Webcast and Conference Call

The Company will host a webcast and conference call on Monday, May 4 at 10:30am EDT / 2:30pm UTC to discuss the results of a definitive feasibility study on the First Cobalt Refinery. Interested parties are welcome to follow the presentation and participate in a question and answer session by webcast or conference call as follows:

Webcast Link: https://produceredition.webcasts.com/starthere.jsp?ei=1309732&tp_key=ac34f871e4

Call Dial-in:

416-764-8609 (Direct)

1-888-390-0605 (North America toll free)

No conference code required

A recording of the presentation will be available for playback for one week following the live call. Playback instructions will be available on the Company’s website.

About First Cobalt

First Cobalt owns North America’s only permitted cobalt refinery. Cobalt refining is a critical component in the manufacturing of batteries for electric vehicles, consumer electronics and industrial applications. Cobalt is a critical mineral and forms a foundational piece of the next generation of the North American auto sector. First Cobalt also owns an advanced cobalt project in the United States and controls significant mineral assets in the Canadian Cobalt Camp.

On behalf of First Cobalt Corp.

Trent Mell

President & Chief Executive Officer

For more information visit electrabmc.com or contact:

Sabrina Gunness

info@electrabmc.com

+1.416.900.3891

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Note Regarding Forward-Looking Statements

This news release may contain forward-looking statements and forward-looking information (together, “forward-looking statements”) within the meaning of applicable securities laws and the United States Private Securities Litigation Reform Act of 1995, which relate to the proposed development of the First Cobalt Refinery, the intended processing of cobalt hydroxide feedstock at the First Cobalt Refinery and the ability to secure financing and feedstock materials necessary to commence production at the First Cobalt Refinery. All statements, other than statements of historical facts, are forward-looking statements. Generally, forward-looking statements can be identified by the use of terminology such as “plans”, “expects', “estimates”, “intends”, “anticipates”, “believes” or variations of such words, or statements that certain actions, events or results “may”, “could”, “would”, “might”, “occur” or “be achieved”. Forward-looking statements involve risks, uncertainties and other factors that could cause actual results, performance and opportunities to differ materially from those implied by such forward-looking statements. Factors that could cause actual results to differ materially from these forward-looking statements are set forth in the management discussion and analysis and other disclosures of risk factors for First Cobalt, filed on SEDAR at www.sedar.com. Although First Cobalt believes that the information and assumptions used in preparing the forward-looking statements are reasonable, undue reliance should not be placed on these statements, which only apply as of the date of this news release, and no assurance can be given that such events will occur in the disclosed times frames or at all. Except where required by applicable law, First Cobalt disclaims any intention or obligation to update or revise any forward-looking statement, whether as a result of new information, future events or otherwise.

Appendix 1

Location Map – First Cobalt Refinery

Appendix 2

Site Rendering – Expanded Refinery

Appendix 3

Pictures of the First Cobalt Refinery

Image 1. First Cobalt Refinery in Ontario, Canada

Image 2. Current flow sheet configuration of the First Cobalt Refinery